Unifying logistics control towers

Case Study

Unifying 5 logistics control towers under a single digital platform eliminated highly manual work and surfaced real insights, driving impressive efficiency gains and allowing resources to be redeployed to more strategic areas of focus.

Isolated, manual processes made improving a complex global logistics operation impossible

Our customer’s complex global logistics operation spans 90 countries, using 5 logistics control towers in Europe, Africa, Asia Pacific, the Middle East & North America.

Prior to e2log:

- Each control tower executed thousands of shipments every year, in complete isolation from one another.

- Logistics execution was done via the brute force of emails and phone calls, with data manually collated onto massive, unwieldy spreadsheets.

- Lacking a single platform to orchestrate this complex global operation, the control towers had no way to efficiently coordinate handoffs with each other.

Deploying a single source of truth brought the whole logistics process into sharper focus

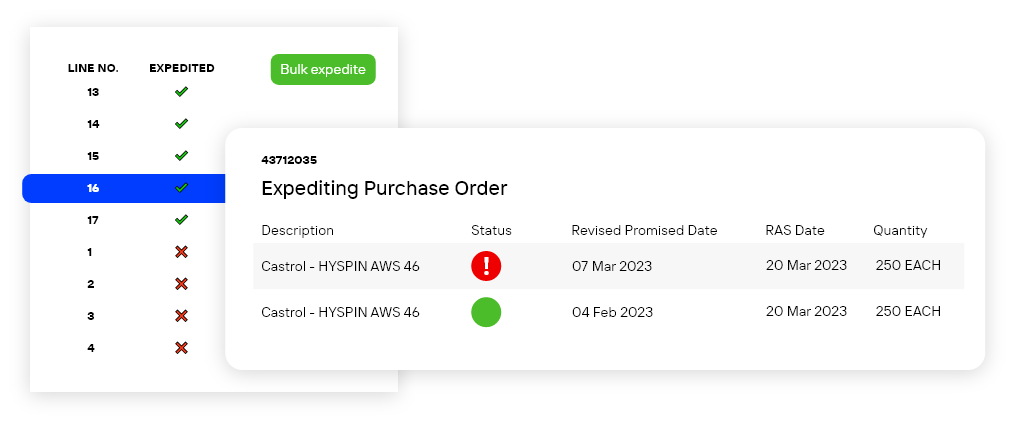

- Real-time: All 5 logistics control towers were brought under a single real-time system.

- Clarity: Separate user groups for each tower enabled a clear assignment of users and logical demarcation of geographical coverage and operational responsibilities.

- Single source of truth: The manual tracking and updating that plagued the globally-distributed team for years gave way to a remote, cloud-based single source of truth.

The unification of 5 control towers across 90 countries helped the team exceed productivity and efficiency goals

Unification helped replace the chaos of emails, spreadsheets and phone calls with a single cloud-based platform driving the orchestration of a complex international logistics operation.

As each transaction was logged, e2log recorded it in a real-time data repository accessible across all control towers.

Because the performance of each control tower could now be measured, analyzed, and compared – and because the highly manual work of managing control towers via spreadsheets, phone calls, and emails was eliminated – the productivity and efficiency of the control towers improved dramatically and ~60% of the resources were re-deployed within the company.

Learn How You Can Unify Control Towers Today

With the ability to unify control towers to gain the visibility and control you need, plus our team of experts ready to help you, improving productivity and efficiency has never been easier.